automatic shrink wrap machine is more than just packaging; it's a strategic asset.

|

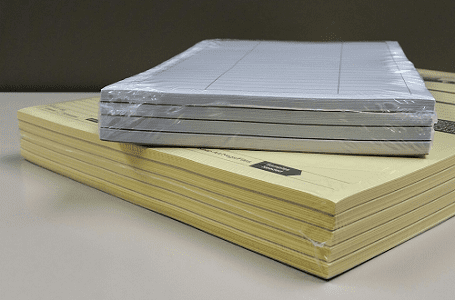

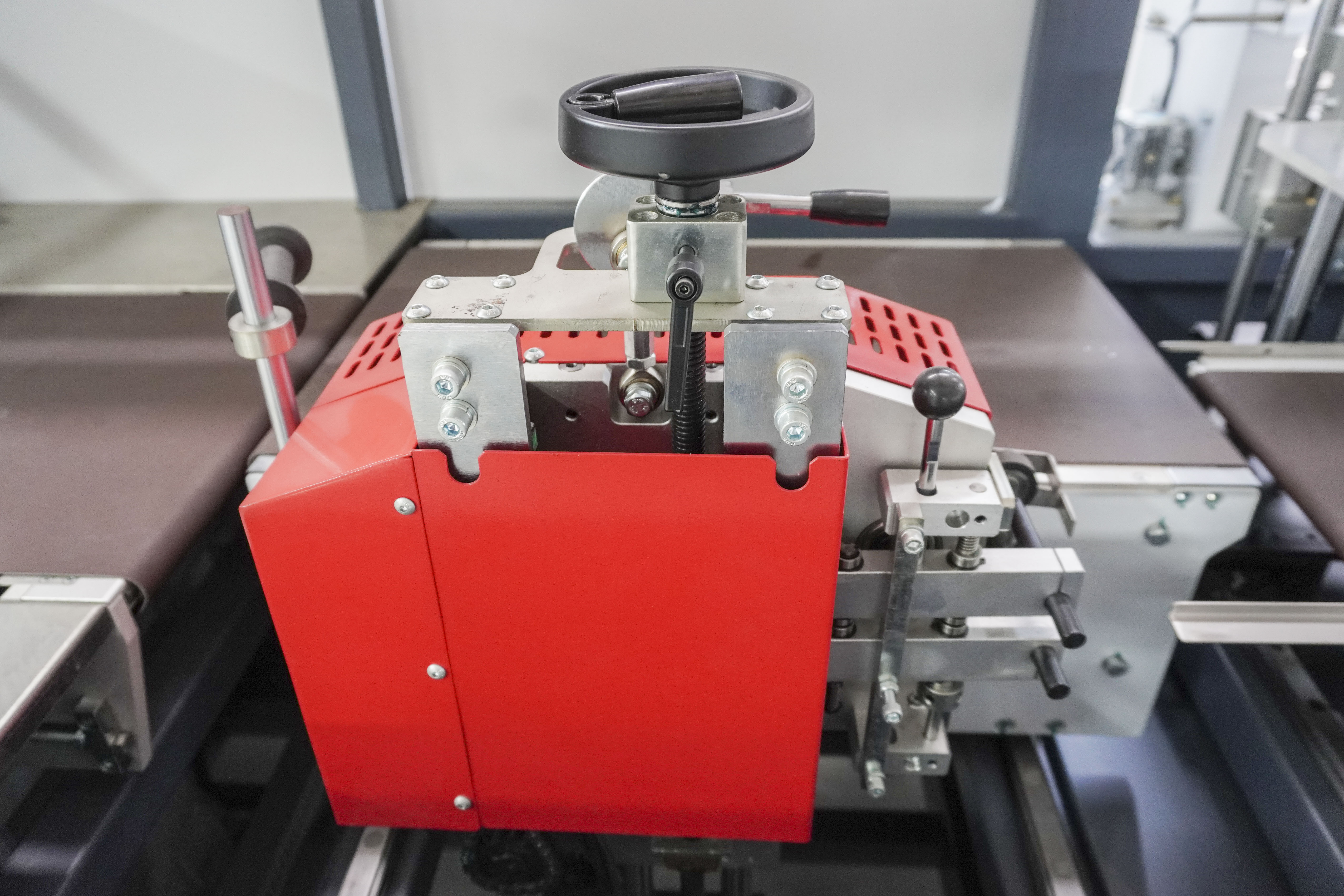

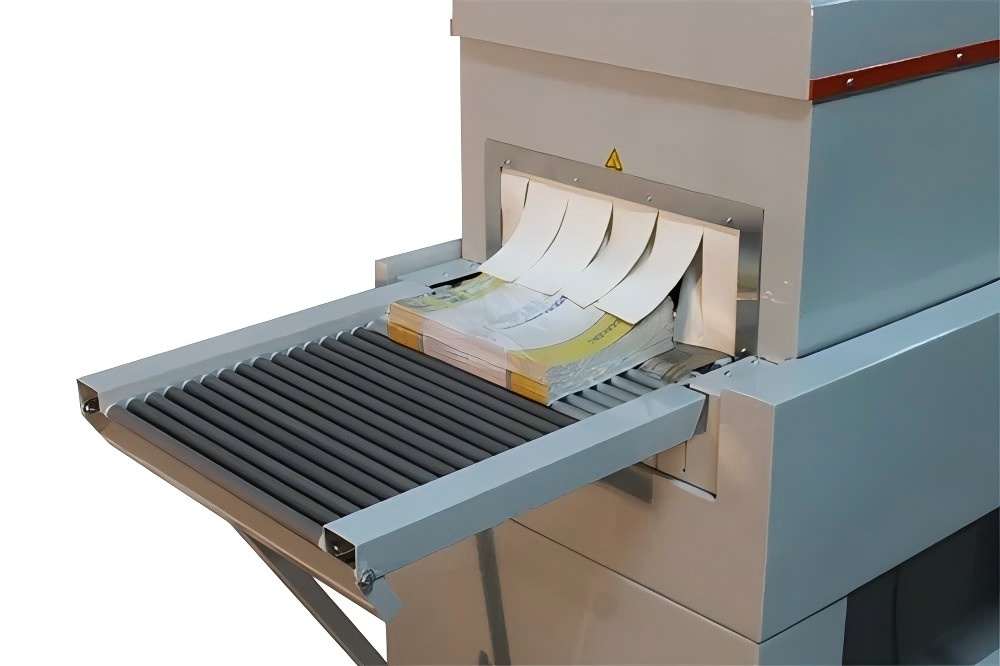

Securing and protecting bound goods demands technology that is both robust and intelligent. Modern book shrink wrapping machines represent the cutting edge of automatic packaging for the book binding industry. Moving far beyond basic wrapping, these systems integrate advanced features like servo motor drive, precision electric sensors, and integrated thermal control to deliver unmatched reliability and quality for packaging hardcover books, paperbacks, notepads, spiral bound notebooks, journals, diaries, and wire or glued bound materials. This book packaging equipment ensures products are shrink wrapped impeccably for both shipping durability and attractive retail-ready presentation, safeguarding against dirt and debris throughout the supply chain. Precision engineering defines every stage. The automatic sealing and cutting unit exemplifies this. Driven by a high-performance servo motor, it ensures accurate and consistent movement. Two group electric eyes (horizontal and vertical) provide versatile sensing, allowing the machine to automatically adjust the cutting size for different product dimensions and orientations fed via the automatic book feeding table. This sensor input, processed alongside timer settings, guarantees a perfect film fit for every item, from slim glued bound booklets to thick hardcover volumes. The sealing itself uses a hot air knife with Teflon coating and constant temperature heating, achieving continuous hot cutting at 1 meter per second for stable packing with no adhesion and no breakage.  The heat shrinking part leverages smart thermal management. An integrated heat controlling system governs the thermal cycle shrinker, ensuring optimal temperature stability. The capability for freely adjustable wind direction is critical; it allows operators to direct heat precisely, ensuring uniform shrinkage around complex geometries inherent in book binding products – such as the open edge of a spiral bound notebook or the embossed cover of a hardback type of book. Double layer insulation curtains enhance this efficiency, promoting energy saving and maintaining a constant temperature environment for flawless, bubble-free results that perfectly showcase products.  Underpinning this performance is exceptional reliability, vital for high output operations in print and paper, packaging and distribution facilities. The electronic control part is built using components from globally trusted brands like Panasonic, Omron, and IFM. This commitment to quality ensures outstanding equipment operation stability and a remarkably low failure rate, minimizing costly production interruptions. The modular design, where four units can be separately moved according to the site layout, further enhances uptime by simplifying maintenance and reconfiguration.  This automatic shrink wrap machine is more than just packaging; it's a strategic asset. It tackles the core challenges of packaging books & binding: replacing slow, error-prone hand wrapping with high speed (up to 80 pieces per minute) automation, drastically reducing labor costs and eliminating bottlenecks. Its compatibility with various polymer plastic compound films, from low gauge polyolefin for clear retail display to thick polyethylene for rugged shipping protection, makes it incredibly versatile. By delivering high efficiency and low cost, coupled with zero pollution and reliable protection, this machine is the ideal process equipment for forward-thinking businesses aiming to optimize their finishing lines and deliver impeccably protected books, notebooks, and journals to market. |

| Tag:Book Protection,book binding,Shrink Wrapping,heat shrinking,book shrink wrapping machine |

Please Leave Your Messenger Here!

We will do our best to make your business prosperous!