Compare the HX680 Classic against the Muller Martini 60D. Discover why the HX680's 7-clamp system and hydraulic pressure offer superior stability and spine quality.

|

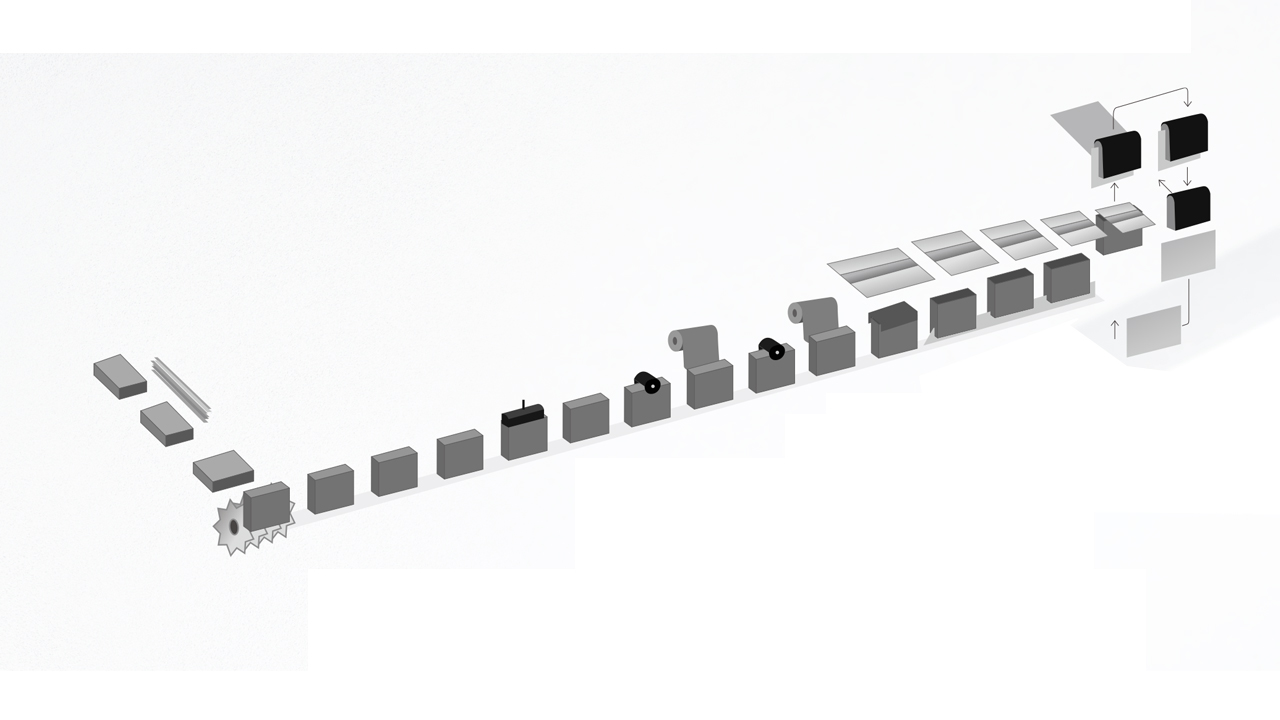

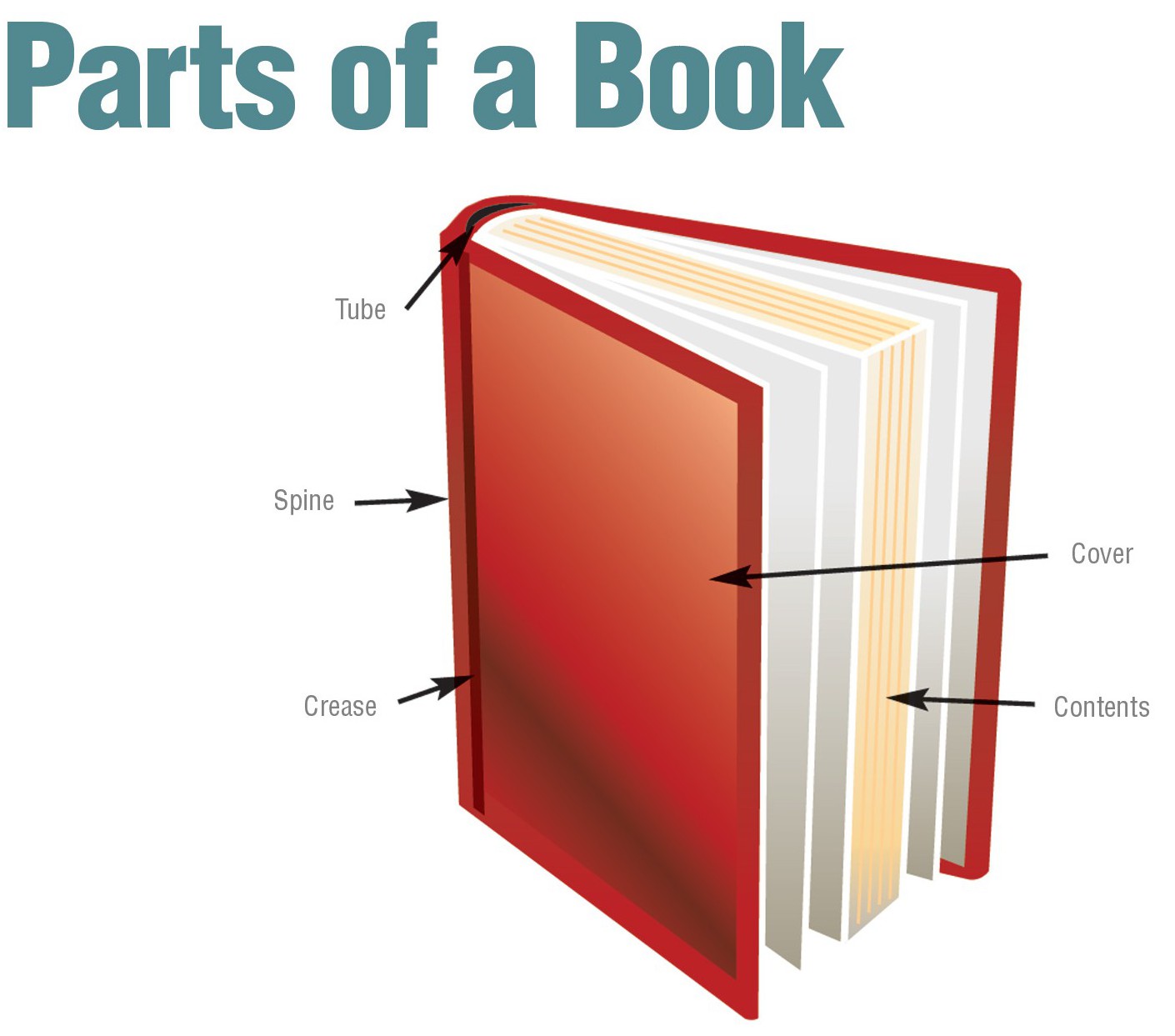

When investing in a hardcover bookline, savvy buyers look beyond the brand name to the engineering under the hood. While the Muller Martini (MM) 60D has been a market player, the HX680 Classic Hardcover Book Production Line has emerged as a superior alternative in critical stability and quality metrics.  Why the HX680 Classic Outperforms:  1. Superior Stability (7 Clamps vs. 6 Clamps): The HX680 utilizes 7 clamp plates compared to the MM 60D's 6. At high speeds (60 books/min), this extra station reduces vibration by 20%, ensuring smoother transmission and fewer jams.  2. Hydraulic vs. Pneumatic Pressure: Achieving a sharp book joint requires immense pressure. The HX680 employs a 20T Nitrogen Hydraulic System, whereas the MM 60D relies on pneumatic pressure. This results in sharper, more defined book spines without the need for excessive spray glue. 3. Scratch-Free Case Feeding: The HX680 features a continuous case feeder with a rotary nozzle (pre-spin) design. Unlike the belt-driven system of the MM 60D, which can scratch delicate cover materials, the HX system protects your premium finishes. 4. Handling Diverse Paper: Thanks to its long Splitter Sword design with air-assist, the HX680 handles everything from thin 28g Bible paper to thick 250g cardstock without tearing—a limitation often found in the wider-blade design of competitors. For a better Return on Investment (ROI) and superior binding quality, the choice is clear. |

| Tag:HX680 Classic,Muller Martini,Industrial bookbinding machinery,Hardcover manufacturing,hardcover book |

Please Leave Your Messenger Here!

We will do our best to make your business prosperous!